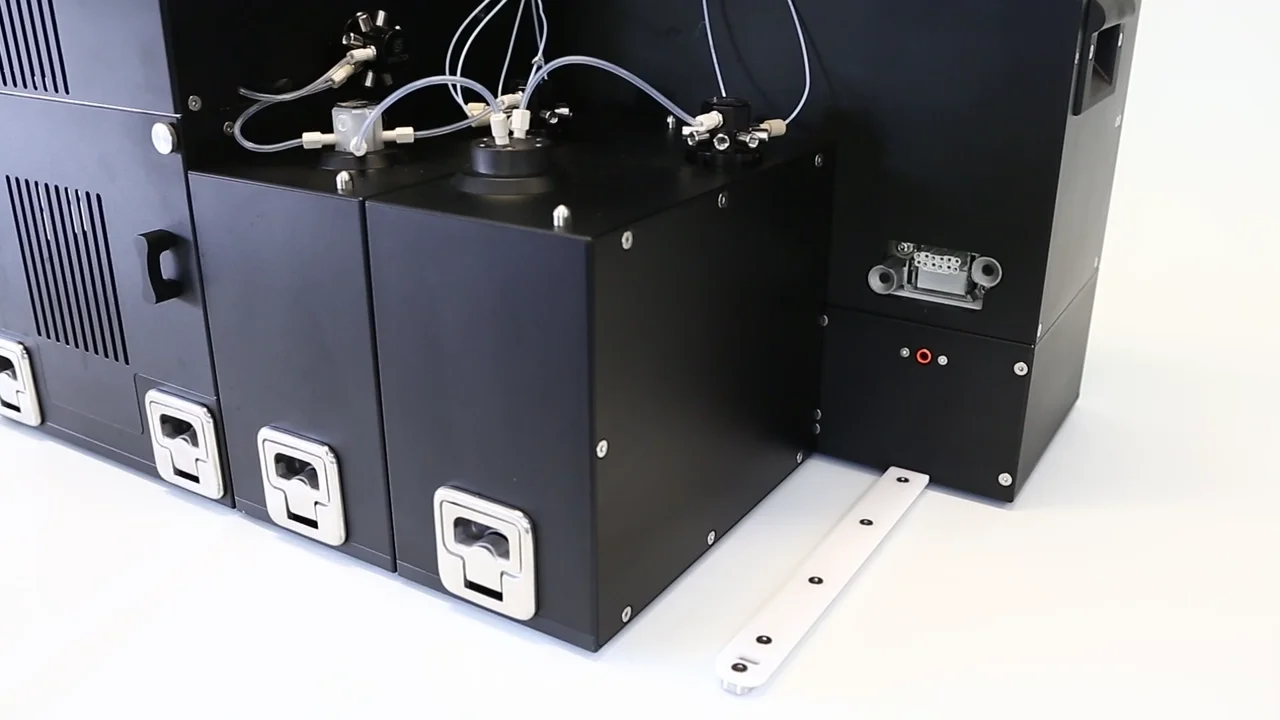

ChemiBASE

- Integrated PLC System

- Onboard Server Power

- Inert Gas Management

- Vacuum Delivery

Integrated Control Hub

The ChemiBASE is an all-in-one control module that centrally manages your system with an integrated PLC, embedded server, and power supply, while precisely regulating nitrogen pressure and controlling compressed air and vacuum for seamless operation.

Key Features

- Its intelligent, grid-based architecture makes it effortless to integrate, upgrade, or interchange extension modules. This design ensures that the Cheminizer, through its ChemiBASE, is not only versatile but also future-proof, enabling researchers to scale complexity, integrate novel methodologies, and continuously push the boundaries of organic synthesis automation.

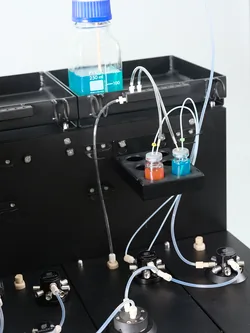

Storage Under Inert Atmosphere

Maximize reagent shelf-life and secure result reliability. Store under inert atmosphere to prevent degradation and guarantee consistent, high-quality outcomes.Master Air-Sensitive Chemistry with Automated Precision

Our advanced system delivers unparalleled control for your most demanding reactions. Experience fully automated vacuum/nitrogen (or argon) cycles that meticulously inert your chemical reactor, guaranteeing a pristine environment and ensuring your sensitive transformations proceed with absolute confidence and superior results.Effortless Distillation

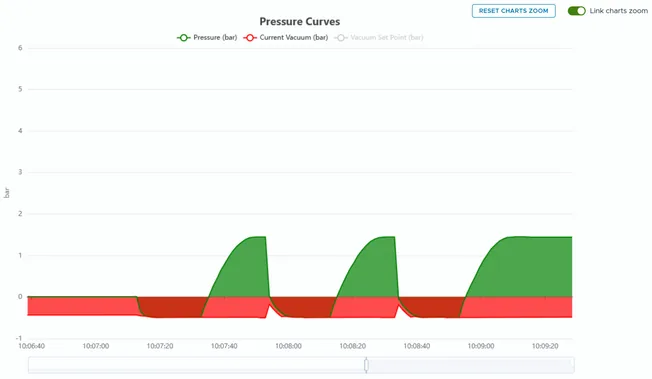

Achieving rapid, complete solvent evaporation. Our integrated thin film, fast heating, and controlled vacuum system makes short work of all solvents, including high boiling point solvents like DMF and DMAc.Automated Vent-vac Control

Automated pressure management ensures safe operations with an instant-trigger vent valve. Applied vacuum at precise set points enables controlled distillations and gentle reagent aspiration, boosting your process efficiency.

Future Innovation

Automated Reactive Gas Introduction

Master gas-liquid reactions. Independent supply lines and precision pressure regulators ensure accurate introduction of critical reagent gases (Ammonia, Chlorine, Hydrogen), optimizing your processes.

In-line Reaction Monitoring

Unlock seamless integration and expanded capabilities. Cheminizer's robust control over third-party equipment is already a reality and continues to grow. By pairing Cheminizer with your UV detector and HPLC pump, you can achieve in-line Analytical HPLC monitoring and fully automated semi-preparative HPLC purification, streamlining your workflow like never before.

Specifications

| Power Supply | 110/230V AC 50-/60Hz |

|---|---|

| Server | Ubuntu Based System |

| Connectivity | wired (RJ45) or wireless connection |

| Inert Gas Pressure | 1.5 bar (adjustable) |

| Adjustable "Low Flow" | From 1 mL/min to 150 mL/min |

| Fixed High Flow | 1.5 L/min |

| Compressed Air Pressure | 6 bar |

| Vacuum | Down to 100 mbar |

| Vacuum Control | Yes |

| Overpressure Safestop | Over 6 bar |

| Dimensions | 63.0 x 18.5 x 38.9 cm (L x D x h, without extension rails) |

| Weight | 20.4 kg (13.4 + 7.0 kg) |