How it Works

Thanks to the increased surface/volume ratio and precise control of reaction parameters, these systems enable enhanced kinetics, increased selectivity, and significant waste reduction.

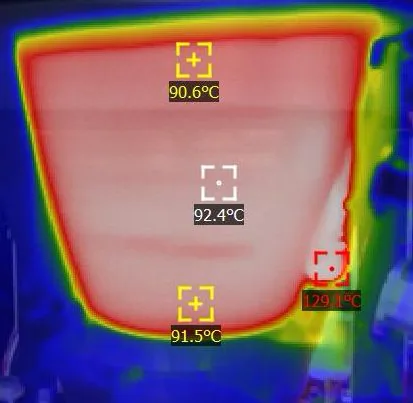

The micrometer or millimeter thickness of the film promotes efficient mass and heat transfers, paving the way for transformations inefficient (or poorly efficient) in traditional stirred tank reactor.

This results in processes that are more efficient, safer, and more sustainable, ideal for cutting-edge applications requiring high purity and optimized yield.